news

service

contact

recruitment

中文站

news

service

contact

recruitment

中文站

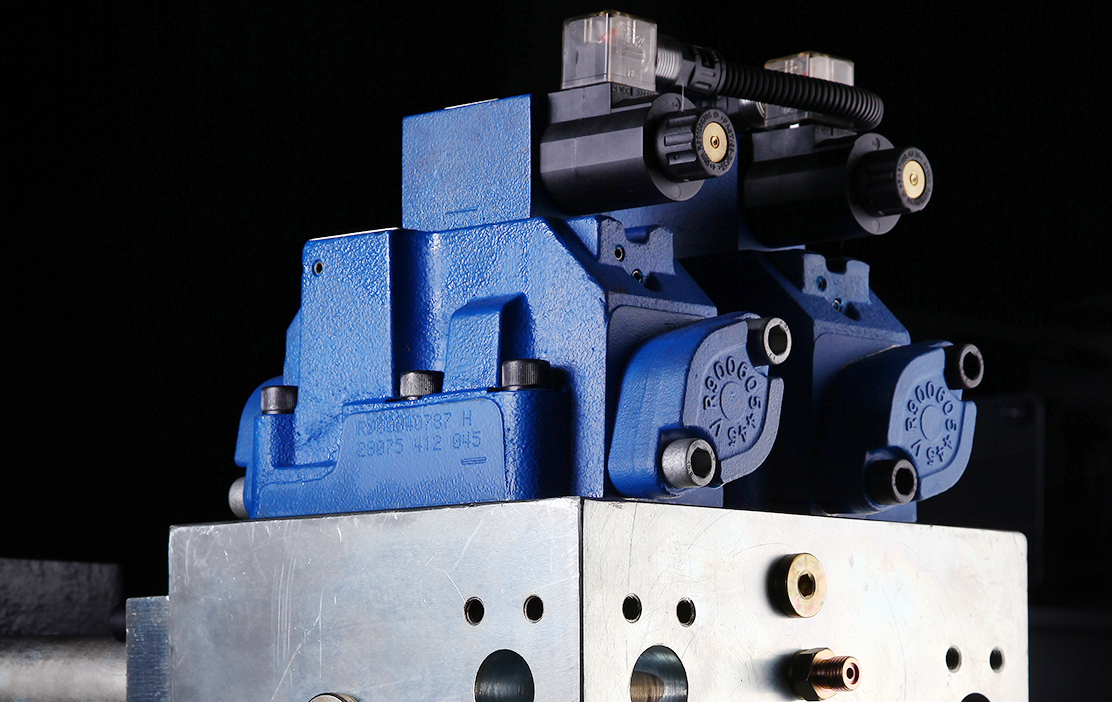

+

Using high-performance hydraulic components of international famous brands, opening and closing die, ejecting, Chinese characters, adjusting die and other actions using high-efficiency and energy-saving hydraulic servo system, with mature and perfect functions such as neutron, wring teeth, etc. , can realize the linkage of opening die and material storage, shorten the molding cycle. The perfect combination of servo motor and internal gear pump, through high-precision sensor to form pressure and flow closed-loop control, greatly improve the accuracy of equipment. Open and close mode proportional reversing valve is optional, so that the position accuracy is more accurate, faster response.

+

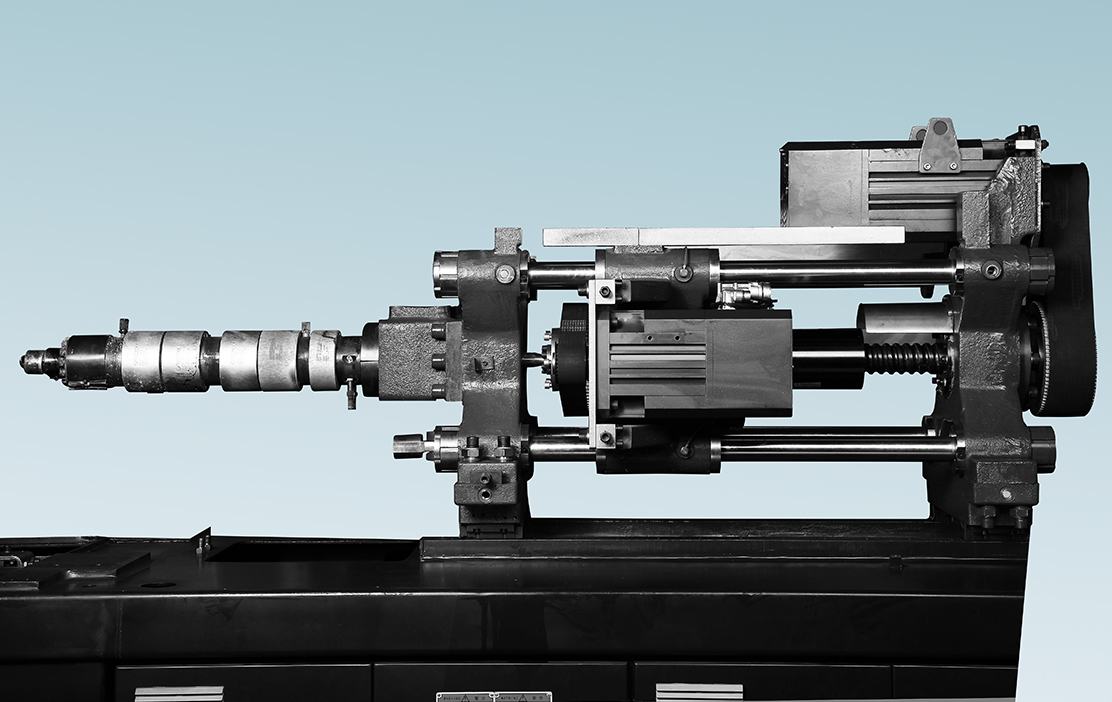

Plastic and injection glue are driven by servo motor directly. The system uses the famous foreign brand Spider Silk Pole, cooperates with the ball silk pole special support bearing to guarantee the ejection device the structure to be accurate, the high efficiency. Injection pressure sensor has strong anti-interference and high resolution. The position of the screw injection is accurate, and the speed is controllable. It can meet the requirements of thick wall and high appearance. All hard steel alloy screw design, high strength, good corrosion resistance, longer service life. Professional automatic lubrication system, injection ball screw using high-pressure, wear-resistant, heat-resistant, water-resistant high-performance grease lubrication, pre-plastic bearings and synchronous pulley high load-bearing to improve the machine service life.

+

+

Rapid response, high production efficiency, high repetition accuracy, saving raw materials.

+

Energy saving: during the cooling phase, the motor does not need to work, and the power consumption is 0.

Water and oil saving: compared with the traditional hydraulic power system hydraulic oil consumption reduced by 1/4 ~ 1/3, can achieve no cooling, thus greatly saving water.

+

Less noise emission: Hydraulic System Noise Control within the scope of national standards.

Waste heat and cooling energy needs low, more suitable for the production environment with Air Conditioning: Injection Molding Machine from start-up to enter the steady-state oil temperature rise 8 °C-10 °C.